Includes 53 different calculations.

Calculation of air leakage through doors.

Q ca dp n.

This air leakage is speci fied as a function of the rate of use of the door the door geom.

Equations displayed for easy reference.

The door undercut gets all the attention but the sides and top of the door also allow a good amount of air to flow through.

Air leakage on the other hand refers to the seal at the overhead door guides head and hood while the rolling door is in the closed position.

Online calculator to quickly determine air flow rate through an orifice.

Lets say the door has a total area of 30 sq.

Thermal resistance is measured using r value and u factor.

Thermal resistance is a huge factor that affects the energy performance of insulated roll up garage doors when they are in the closed position.

Now how do i calculate the leakage area to insert in the equation.

So if you can get 60 cfm under the door you can get about 120 cfm total.

Abstract a generalized relationship is presented for determining air flow rates through narrow gaps around door edges.

Semmelhack believes the air flow through the sides and top of the door is equal to the air flow through the undercut.

An air vent has a dimension of 30 cm x 3 cm and is fitted with a gauze insect screen that reduces the effective area of the opening by 40.

Air leakage through automatic doors grenville k.

Dictive calculations of air leakage through door gaps over a wide range of flow conditions.

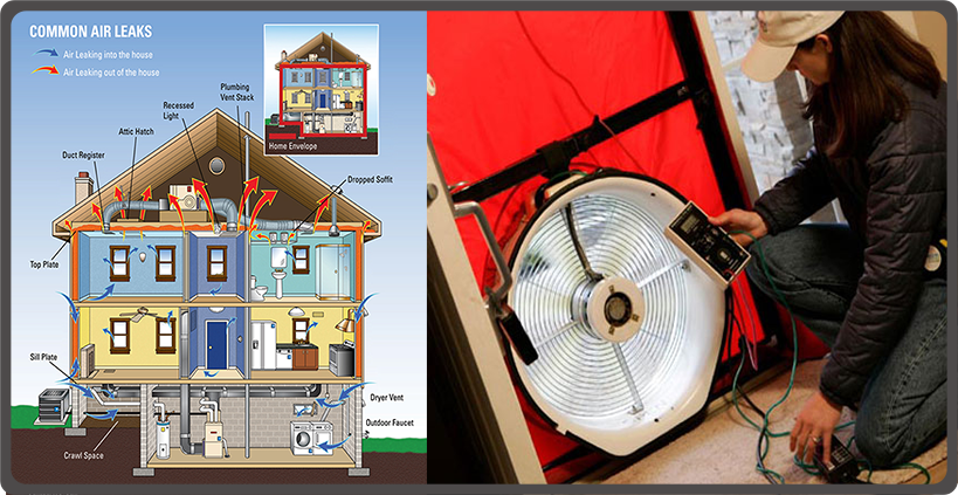

Air leakage is sometimes called infiltration which is the unintentional or accidental introduction of outside air into a building typically through cracks in the building envelope and through use of doors for passage.

The relationship provides values of leakage rates for steady laminar flow through gaps over a wide range of pressure differences and eliminates approximations associated with the often inappropriate use of discharge coefficients and exponents in the flow nist equation.

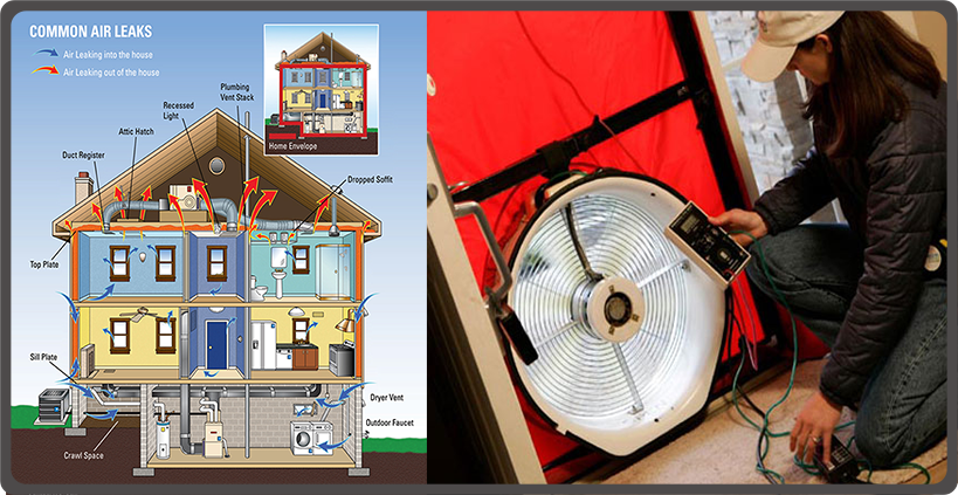

Fellow ashrae rebecca upham member ashrae chen hui abstract a method has been developed to estimate the air leakage through high use automatic doors.

The purpose of this paper is to provide a relation ship capable of predicting flow through gaps of prescribed geometry and to make comparisons with available experimental data on flow through gaps and around selected door assemblies.